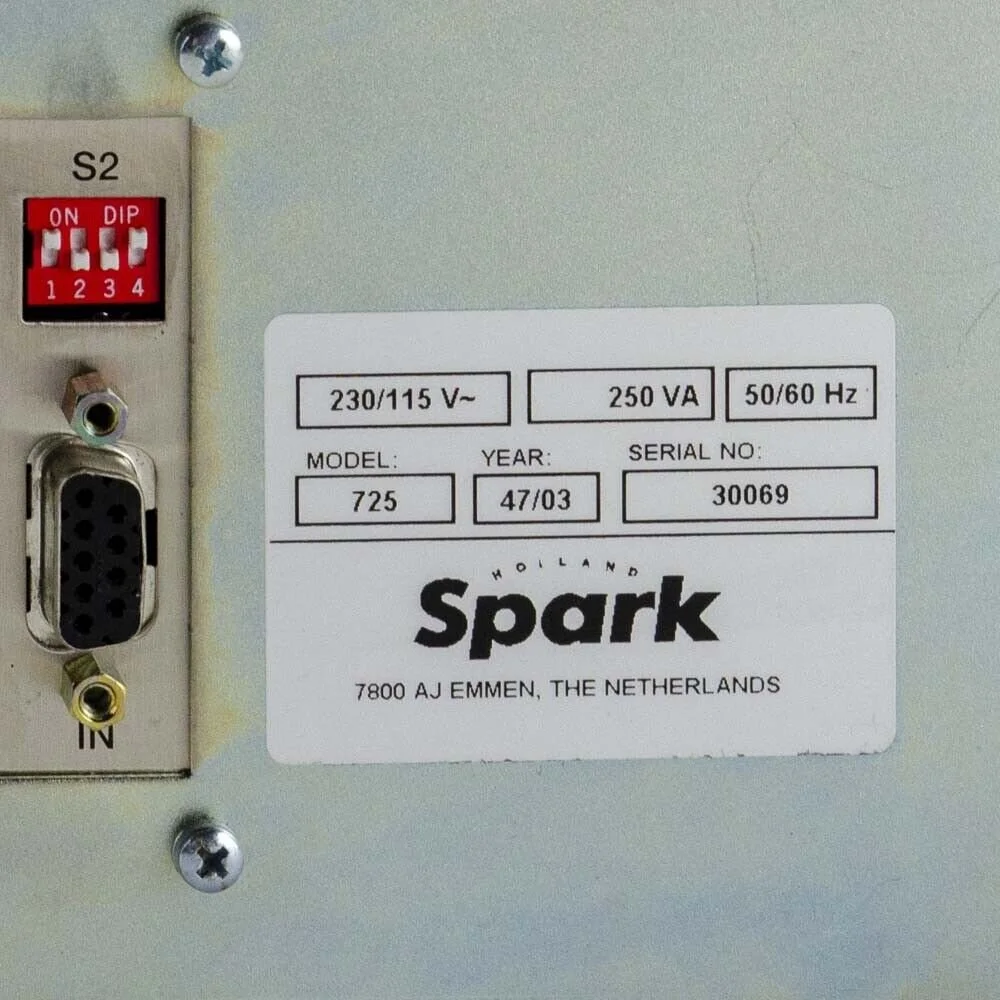

Image 1 of 5

Image 1 of 5

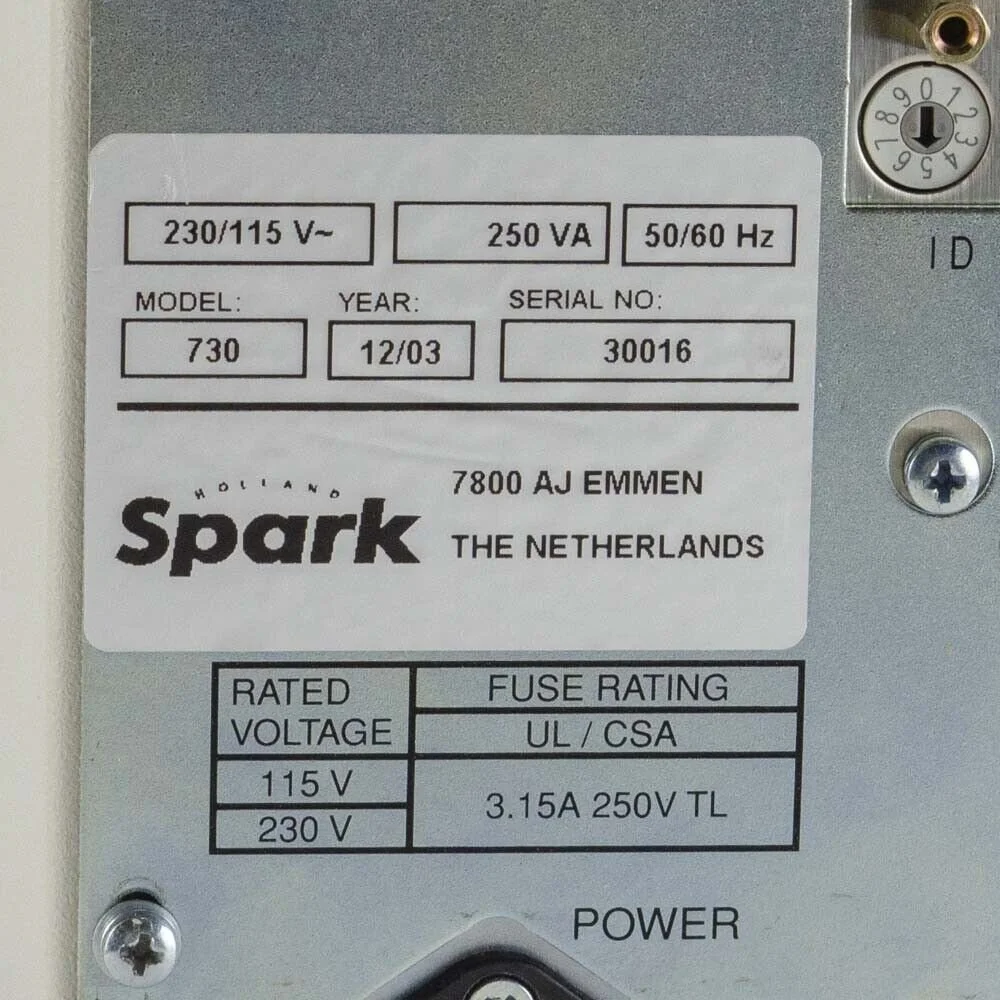

Image 2 of 5

Image 2 of 5

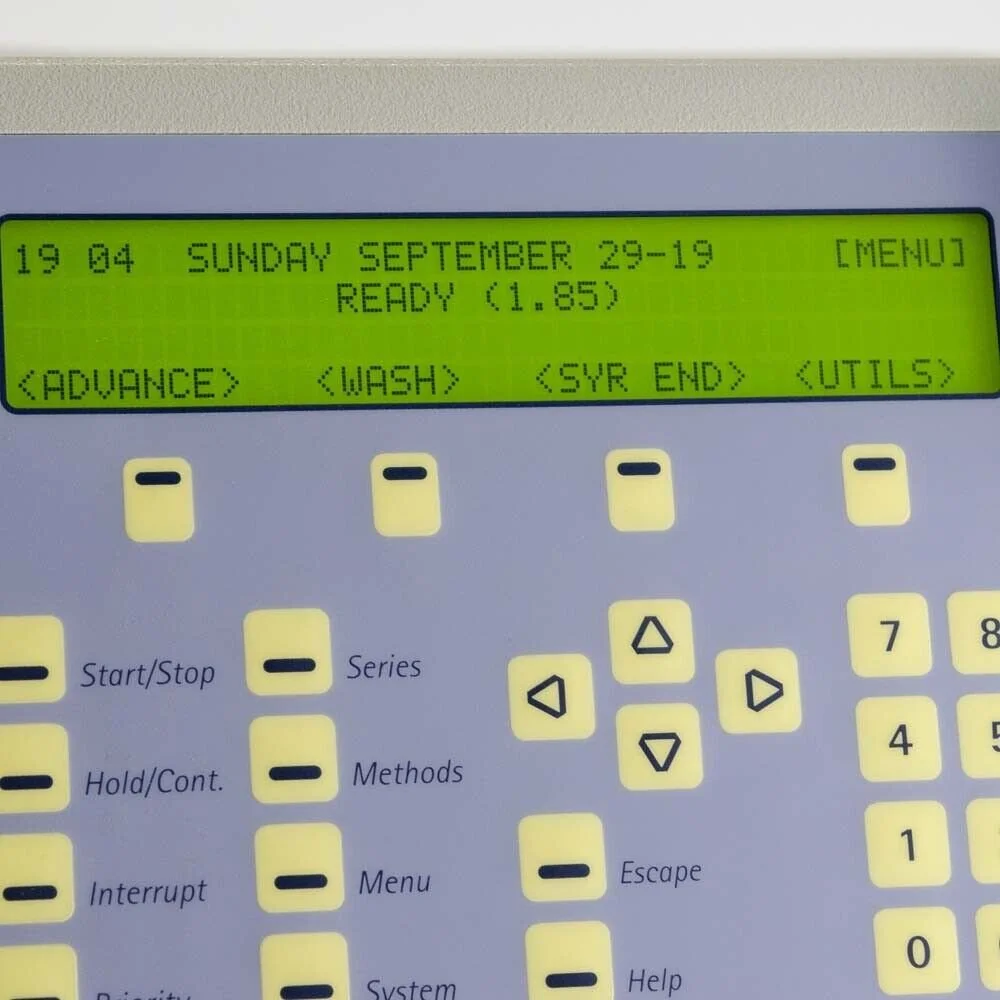

Image 3 of 5

Image 3 of 5

Image 4 of 5

Image 4 of 5

Image 5 of 5

Image 5 of 5

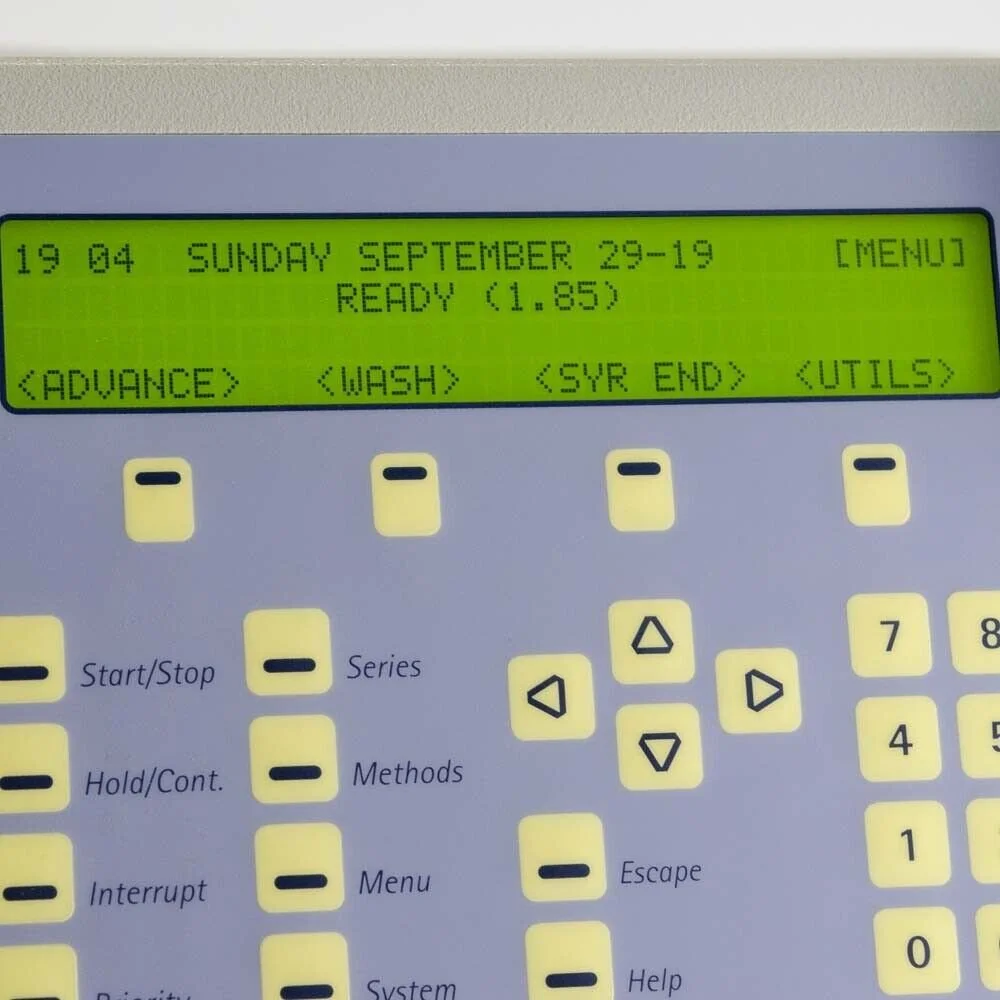

Spark Holland Model 900 Triathlon Autosampler

Spark Holland Model 900 Triathlon Autosampler

Actual item displayed. Comes with 30 day money back guarantee. Specs listed below were taken from manufacturers literature.

| GENERAL | |

| Sound pressure level | < 70 dB |

| Working temperature | 10 – 35 °C |

| Storage temperature | -25 / 60 °C |

| Humidity | 20-80% RH |

| Installation category | Category P (according to IEC 1010) |

| Pollution degree | Degree 2 (according to IEC 1010) |

| Sample capacity | 96 vials of 1.5 ml (STD), 12 vials per segment 72 vials of 4.0 ml (LSV), 9 vials per segment 48 vials of 10ml (Super LSV), 4 vials per segment 160 micro vials of 0.5 ml, 20 vials per segment |

| Vial dimensions | Maximum vial height: 47 mm inclusive cap. Minimum vial height: 32 mm inclusive cap. |

| Loop volume | 5 – 1000 µl |

| Injection volume | 1µl – 1 ml, with 1 µl increment |

| Injections per vial | max. 9 (Volumes are programmable for each injection) |

| Injection methods | Flushed loop injections Partial loopfill injections µl pick-up injections (without sample loss) |

| Needle wash | Programmable: Wash between injections Wash between vials Wash at end of series |

| Wash solvent | 250 ml internal wash solvent bottle |

| Dispenser syringe | 100 µl, 250 µl (standard), 500 µl ,1000 µl or 10ml (only with userprog) |

| Vial detection | Missing vial detection by vial sensor |

| Sample access | < 10 seconds |

| Headspace pressure | Built-in compressor |

| Pre-puncturing septa | With air needle, dual needle action |

| Switching time injection valve | electrically < 100 msec |

| Piercing precision needle | ± 0.6 mm |

| Priority sample | Free programmable |

| ANALYTICAL PERFORMANCE | |

| Reproducibility | Capped and sealed vials |

| •Full loop injections | RSD£ 0.3% |

| •Partial loopfill injections | RSD£ 0.5% injection volumes > 5 µl, with headspace pressure on the vial and 30µl pre-flush with air-segment |

| •µl pick-up injections | RSD£ 1.0% injection volumes > 5 µl, with headspace pressure on the vial |

| ELECTRICAL | |

| Power requirements | 115 VAC; ±10%; 50/60 Hz; 250 VA 230 VAC; ±10%; 50/60 Hz; 250 VA |

| Fuses | For 115 VAC; two 5.0 AT-fuses (slow, ¼” x 1¼”, UL/CSA) For 230 VAC; two 2.5 AT-fuses (slow, 5 x 20 mm, IEC127) |

| COMMUNICATION | |

| Outputs | Inject marker (Relay & TTL) Vial marker (Relay & TTL) Labelled vial marker(Relay & TTL) Stop I/O (Relay & TTL) BCD output (TTL) 4 Auxiliary outputs (Relay) 2 Programmable outputs (Relay) Alarm output (Relay) 4 bit time base (TTL) |

| Inputs | Next injection input (TTL) Next vial input (TTL) Freeze input (TTL) Stop I/O (TTL) 4 programmable inputs (TTL) |

| Serial communication port | RS 232C or Multilink |

Shipping

Shipping options vary by item. Some of our inventory is too big to ship via any method but freight. For smaller individual items (valves, sensors, fittings, etc), Fed Ex, UPS, or USPS will be used. .

Please contact us if you have any questions.

Service

Disclaimers

If you are not satisfied with your purchase for any reason, please let us know within 30 days of receipt in order to return the item. Equipment is located in our warehouse in Wichita, Kansas. Shipping measurements and shipping weight are estimated to the best of our knowledge. In most circumstances, the item pictured will be the item you receive. We may use stock photos on listings with multiple items available for sale. Equipment licenses are not transferable.

Spark Holland Model 900 Triathlon Autosampler

Actual item displayed. Comes with 30 day money back guarantee. Specs listed below were taken from manufacturers literature.

| GENERAL | |

| Sound pressure level | < 70 dB |

| Working temperature | 10 – 35 °C |

| Storage temperature | -25 / 60 °C |

| Humidity | 20-80% RH |

| Installation category | Category P (according to IEC 1010) |

| Pollution degree | Degree 2 (according to IEC 1010) |

| Sample capacity | 96 vials of 1.5 ml (STD), 12 vials per segment 72 vials of 4.0 ml (LSV), 9 vials per segment 48 vials of 10ml (Super LSV), 4 vials per segment 160 micro vials of 0.5 ml, 20 vials per segment |

| Vial dimensions | Maximum vial height: 47 mm inclusive cap. Minimum vial height: 32 mm inclusive cap. |

| Loop volume | 5 – 1000 µl |

| Injection volume | 1µl – 1 ml, with 1 µl increment |

| Injections per vial | max. 9 (Volumes are programmable for each injection) |

| Injection methods | Flushed loop injections Partial loopfill injections µl pick-up injections (without sample loss) |

| Needle wash | Programmable: Wash between injections Wash between vials Wash at end of series |

| Wash solvent | 250 ml internal wash solvent bottle |

| Dispenser syringe | 100 µl, 250 µl (standard), 500 µl ,1000 µl or 10ml (only with userprog) |

| Vial detection | Missing vial detection by vial sensor |

| Sample access | < 10 seconds |

| Headspace pressure | Built-in compressor |

| Pre-puncturing septa | With air needle, dual needle action |

| Switching time injection valve | electrically < 100 msec |

| Piercing precision needle | ± 0.6 mm |

| Priority sample | Free programmable |

| ANALYTICAL PERFORMANCE | |

| Reproducibility | Capped and sealed vials |

| •Full loop injections | RSD£ 0.3% |

| •Partial loopfill injections | RSD£ 0.5% injection volumes > 5 µl, with headspace pressure on the vial and 30µl pre-flush with air-segment |

| •µl pick-up injections | RSD£ 1.0% injection volumes > 5 µl, with headspace pressure on the vial |

| ELECTRICAL | |

| Power requirements | 115 VAC; ±10%; 50/60 Hz; 250 VA 230 VAC; ±10%; 50/60 Hz; 250 VA |

| Fuses | For 115 VAC; two 5.0 AT-fuses (slow, ¼” x 1¼”, UL/CSA) For 230 VAC; two 2.5 AT-fuses (slow, 5 x 20 mm, IEC127) |

| COMMUNICATION | |

| Outputs | Inject marker (Relay & TTL) Vial marker (Relay & TTL) Labelled vial marker(Relay & TTL) Stop I/O (Relay & TTL) BCD output (TTL) 4 Auxiliary outputs (Relay) 2 Programmable outputs (Relay) Alarm output (Relay) 4 bit time base (TTL) |

| Inputs | Next injection input (TTL) Next vial input (TTL) Freeze input (TTL) Stop I/O (TTL) 4 programmable inputs (TTL) |

| Serial communication port | RS 232C or Multilink |

Shipping

Shipping options vary by item. Some of our inventory is too big to ship via any method but freight. For smaller individual items (valves, sensors, fittings, etc), Fed Ex, UPS, or USPS will be used. .

Please contact us if you have any questions.

Service

Disclaimers

If you are not satisfied with your purchase for any reason, please let us know within 30 days of receipt in order to return the item. Equipment is located in our warehouse in Wichita, Kansas. Shipping measurements and shipping weight are estimated to the best of our knowledge. In most circumstances, the item pictured will be the item you receive. We may use stock photos on listings with multiple items available for sale. Equipment licenses are not transferable.